To measure the performance indicators of the supply chain, it is important to define clear objectives and relevant key performance indicators (KPIs). Commonly used KPIs include service rate, inventory turnover, operating costs, and lead time.

Supply Chain Performance and competetiveness

In an increasingly competitive economic environment, supply chain performance has become a key factor in business competitiveness. Efficient supply chain management improves costs and product quality and enables rapid response to market changes and customer needs.

The supply chain encompasses all activities involved in the production and distribution of goods and services, from raw materials management to manufacturing processes, storage, logistics and delivery. Companies that master the performance of their supply chain enjoy a competitive advantage and can respond more effectively to ever-changing demand.

Key points

- Effective supply chain management enhances competitiveness

- Controlling chain performance enables rapid adaptation of supply to demand

- Supply chain performance encompasses aspects such as cost, quality, and speed of response

Understanding the supply chain

Supply chain performance is essential to a company's competitiveness. A thorough understanding of the supply chain helps to optimize operations, reduce costs, and improve efficiency. Supply chain analysis is a key tool for achieving this goal.

The supply chain encompasses all the processes involved in managing the flow of materials, information, and finances, from the procurement of raw materials to the delivery of the finished product to the customer. It includes suppliers, manufacturers, distributors, carriers and retailers, among others. Understanding these various elements enables us to better anticipate fluctuations in demand, potential disruptions, and opportunities for improvement.

To improve supply chain performance, it is important to recognize the key factors that shape it. A key aspect is the alignment of corporate and supply chain strategies. This involves defining clear objectives and implementing performance monitoring mechanisms to ensure that these objectives are achieved. Companies must also regularly assess the risks associated with their supply chain and put contingency plans in place to deal with them.

The integration of information technologies is another crucial aspect of supply chain optimization. Data collection and analysis enable processes to be better managed, and informed decisions to be made in real time. Supply chain management systems, such as enterprise resource planning (ERP), can facilitate this integration by automating and streamlining processes.

In short, understanding the supply chain is key to improving business competitiveness. Supply chain analysis, strategy alignment and IT integration are key factors in optimizing supply chain performance and ensuring business success.

The role of supply chain performance

Supply chain performance plays an essential role in a company's competitiveness. Efficient, well-managed sourcing improves responsiveness and operational flexibility, while reducing costs and associated risks.

Firstly, an efficient supply chain optimizes internal processes such as inventory management and production planning. This helps to minimize the costs and lead times associated with these activities, thus improving the company's overall profitability. In addition, good inventory management prevents stock-outs, which can damage the company's reputation and lead to lost sales.

Secondly, a high-performance supply chain fosters collaboration between different stakeholders, such as suppliers, logistics providers and customers. This enables better coordination of information and goods flows, leading to greater efficiency and improved customer satisfaction.

Finally, supply chain performance contributes to a company's resilience in the face of market fluctuations and unforeseen events. A flexible, adaptable supply chain makes it easier to anticipate and manage crisis situations, such as raw material shortages or logistical disruptions. What is more, a well-functioning supply chain offers a competitive advantage over companies that do not have such a tight grip on their operations.

In short, supply chain performance is essential to a company's competitiveness. It enables them to optimize their internal processes, improve collaboration between the various players and strengthen their resilience in the face of market challenges. As a result, companies that invest in improving their supply chain can look forward to sustainable competitive advantage.

Supply chain management

Supply chain performance is essential to a company's competitiveness. Effective supply chain management reduces costs, improves quality and increases flexibility in the face of market fluctuations.

Production flow management

Workflow management is a key element of the supply chain. It includes the planning, coordination, and control of production, considering available resources and capacity requirements.

Optimizing operations is crucial to ensuring smooth, efficient production flows. Companies need to integrate demand forecasting and inventory information systems to improve their ability to react quickly to market changes.

- Demand forecasting: Companies must anticipate future product requirements to adequately plan the resources needed to produce them.

- Inventory management: The inventory must be managed efficiently to minimize costs while meeting production and market needs.

- Production resource planning: Production resources, such as workforce, materials, and plant capacity, must be planned to ensure optimum production.

In short, supply chain performance is a key factor in a company's competitiveness. Efficient management of production flows, among other things, can lead to reduced costs, improved quality, and greater flexibility in the face of market fluctuations.

The importance of visibility in the supply chain

Visibility in the supply chain is an essential element in boosting a company's competitiveness. It enables efficient management of material and information flows, enabling greater responsiveness to unforeseen events and better planning of operations

Stock management is a key aspect of visibility in the supply chain. It involves accurately tracking and controlling stock levels, locations, and movements of goods. This allows companies to optimize their stock management, avoid stockouts, and reduce associated costs.

Supply chain visibility also promotes improved relationships between partners. Effective communication and close collaboration between suppliers, manufacturers, and distributors create a competitive advantage and ensure a continuous and reliable supply of products.

Furthermore, good visibility within the supply chain allows for the rapid identification of problems. This can include delivery delays, quality issues, or demand fluctuations. By quickly spotting these problems, companies can implement corrective actions and minimize the impact on their operations and profitability.

Lastly, visibility in the supply chain contributes to risk management. Companies with good visibility of their supply chain can identify and assess various risks (such as operational, political, or environmental risks) and implement mitigation strategies to ensure the continuity of their activities.

In summary, a visible supply chain is a key element in improving the competitiveness of companies. It allows them to effectively manage their stocks, optimize their relationships with partners, respond quickly to problems, and control the risks associated with their operations.

Supply Chain Optimization

Supply chain optimization is essential for improving the competitiveness of companies. It allows for cost reduction, improved product quality, and a swift response to market changes.

Strategic planning is a key step in optimizing the supply chain. It allows companies to define their goals and priorities and identify improvements to increase logistical operations' efficiency and profitability. These improvements might include adjusting stock levels, selecting suppliers that offer better value for money, or implementing efficient order tracking and management systems.

The integration of technologies also contributes to supply chain optimization. Information systems, such as Enterprise Resource Planning (ERP) and information management systems, allow for the automation and simplification of internal processes, thereby facilitating communication and coordination among various chain actors. Moreover, adopting technologies like the Internet of Things (IoT) and blockchain can enhance product transparency and traceability, leading to better stock and product flow management.

Collaboration is another key factor in optimizing the supply chain. It is crucial to develop strong relationships with suppliers, customers, and logistical partners to ensure effective communication and real-time information sharing. This helps minimize stockouts, avoid delivery delays, and reduce costs associated with stock management and transportation.

Lastly, environmental sustainability is becoming increasingly important in supply chain optimization. Companies need to consider the ecological impact of their logistical activities, for instance, by adopting practices like recycling packaging, using less polluting transport vehicles, or optimizing routes to reduce greenhouse gas emissions.

In summary, supply chain optimization involves numerous actions and considerations, ranging from strategic planning to technology integration and collaboration with external partners. It enables companies to enhance their market competitiveness by reducing costs, improving product quality, and swiftly adapting to market changes.

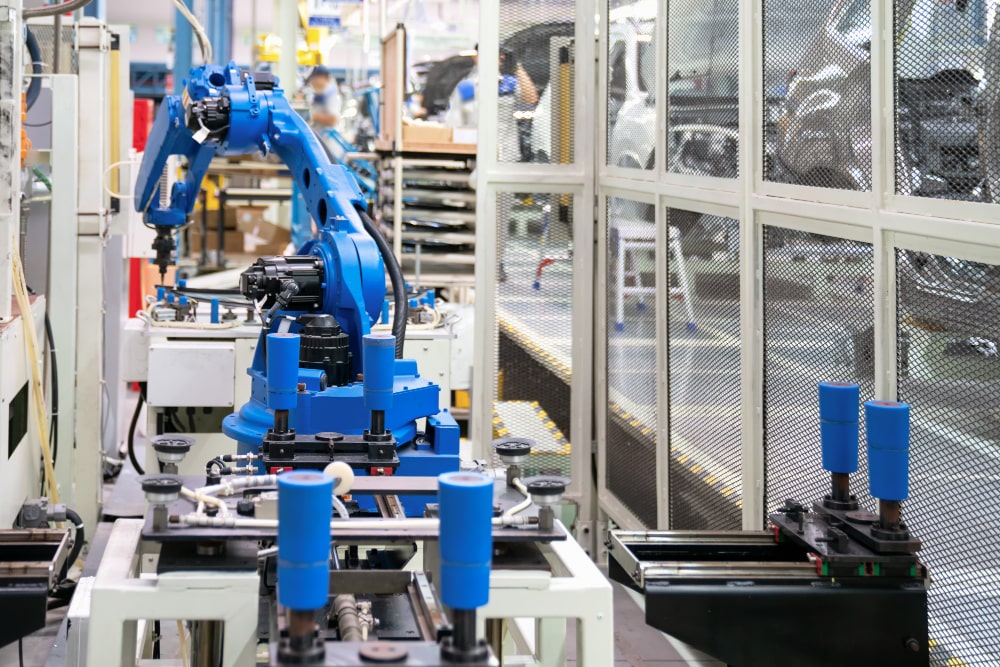

Supply Chain Automation

Supply chain automation is essential for improving the competitiveness of companies. It allows for the simplification of processes, cost reduction, and increased productivity. The impact of automation on a supply chain is significant and offers several advantages.

Firstly, automation helps reduce human errors. Automated systems can process substantial amounts of information accurately and quickly. As a result, companies can better track inventory, orders, and deliveries, leading to improved resource management and increased customer satisfaction.

Furthermore, supply chain automation promotes the standardization of processes. Companies can optimize and harmonize their internal processes, resulting in better coordination between different departments. Additionally, standardization facilitates the integration of suppliers and partners, allowing the entire supply chain to operate more efficiently.

Automation also provides companies with better visibility into their operations. Through the use of automated systems, companies have real-time access to data regarding the status of their supply chain. This is crucial for anticipating potential problems and making informed decisions to continuously improve supply chain performance.

Lastly, automation contributes to enhancing the sustainability of the supply chain. Automated systems help reduce waste and optimize the use of natural resources. Consequently, companies can reduce their environmental footprint and comply with increasingly stringent ecological standards.

In summary, supply chain automation is a key element in strengthening the competitiveness of companies. It allows them to achieve greater efficiency, accuracy, and sustainability, while also promoting better integration of suppliers and partners.

Resource Planning

Resource planning is a crucial approach to optimize supply chain performance and increase the competitiveness of companies. It involves forecasting and organizing the use of human, material, and financial resources to ensure product availability to meet market demands.

In the context of the supply chain, resource planning is essential to ensure a balance between supply and demand. It allows companies to determine the necessary production capacities, reduce storage and transportation costs, and guarantee timely and delay-free delivery.

Resource planning must consider various elements, such as sales forecasts, production and storage capacity, and supplier delivery times. Companies can use technological tools, such as Enterprise Resource Planning (ERP) software and Advanced Planning Systems (APS), to facilitate this task and centralize relevant information.

Among the main steps of resource planning are:

- Needs Analysis: The company must identify market needs and forecast demand based on trends and historical data.

- Evaluation of Available Resources: This involves measuring production capacities, inventory, and human resources to identify potential bottlenecks.

- Production Planning: The company must determine the quantities to produce and the delivery timelines, optimizing resource use and reducing costs.

- Supplier Management: This involves selecting the appropriate suppliers, negotiating contracts, and establishing strong relationships to ensure the quality and availability of the necessary raw materials.

- Monitoring and Control: Companies must continuously monitor the performance of the supply chain to identify deviations from the initial plan and take corrective measures if necessary.

In summary, resource planning plays a pivotal role in enhancing the performance of the supply chain and the competitiveness of companies. It allows for better anticipation and management of market needs, optimization of resource use, and ensures effective interactions with suppliers and customers.

S&OP Tools and Software

S&OP Tool

S&OP (Sales and Operations Planning) tools are essential for improving supply chain performance and company competitiveness. They facilitate collaboration between the various departments of the company, such as sales, production, and logistics. These tools allow for sales forecasting and adjusting production plans accordingly.

Key features of S&OP tools include:

- Data Management: Centralizing company information to facilitate data sharing and access.

- Demand Forecasting: Estimating future sales based on historical data and market trends.

- Production Planning: Coordinating company resources to meet forecasted demand.

- Inventory Management: Optimizing stock levels to minimize costs and maximize product availability.

S&OP Software

S&OP software is designed to automate and simplify the sales and operations planning processes. They offer an intuitive interface and advanced features to facilitate decision-making and adjust plans based on market changes. They also allow for real-time tracking of supply chain performance through dashboards and key performance indicators (KPIs).

By integrating S&OP software tailored to their needs, companies can enhance their supply chain performance and market competitiveness. It is essential to choose the right tool and software based on the company's requirements and objectives.

Conclusion

The importance of supply chain performance for business competitiveness is undeniable. It ensures fast and efficient product delivery, reduces production costs, and optimizes available resources.

By enhancing supply chain performance, companies can gain flexibility and responsiveness to market changes and customer needs. Moreover, an efficient supply chain contributes to customer satisfaction by guaranteeing the quality and availability of products and services.

Lastly, it is essential for companies to invest in technological solutions and employee training to optimize their supply chain management. This approach will improve overall competitiveness and ensure the long-term viability of companies in the market.

Frequently asked questions

Questions about Supply Chain performance

Improving business competitiveness through supply chain management involves optimizing processes, enhancing collaboration with suppliers, and implementing effective management systems. Companies must also strive to reduce costs and lead times, while ensuring product quality and customer satisfaction.

The stakes of supply chain performance for a company's profitability include cost optimization, product quality improvement, lead time reduction, increased flexibility, and customer satisfaction. An efficient supply chain ensures the continuity of operations and minimizes the risks associated with stockouts or delivery delays.

The stakes of supply chain performance for a company's profitability include cost optimization, product quality improvement, lead time reduction, increased flexibility, and customer satisfaction. An efficient supply chain ensures the continuity of operations and minimizes the risks associated with stockouts or delivery delays.

The key success factors for an efficient supply chain include strategic planning, alignment of internal and external processes, cooperation and communication with partners, the use of appropriate technologies, and the implementation of effective measurement and control systems.

To optimize the supply chain, companies can implement various strategies, such as reducing inventory, improving supplier quality, adopting lean practices, using information systems, and implementing integrated planning processes.

Supply chain performance has a direct impact on customer satisfaction, as it influences product availability, delivery times, product quality, and after-sales service. An efficient supply chain allows for better meeting customer expectations and improving the company's competitiveness in the market.