Increase reactivity

PlaniSense helps to improve your responsiveness in a constantly changing industrial and economic context, subject to frequent disruptions.

The challenge: Deciding amidst uncertainty

Manufacturers are facing new challenges as a result of increasingly complex flows, growing uncertainty, tighter regulatory constraints and limited resource availability. Responsiveness to changes and unforeseen events is a major challenge.

To maintain optimum performance, the key lies in detecting the weak signals of coming disruptions, rapidly implementing actions and anticipating the operational consequences.

.jpg?width=651&height=976&name=iStock-858568758%20resize%20(1).jpg)

.png?width=60&height=60&name=Design%20sans%20titre%20(41).png)

Our solution

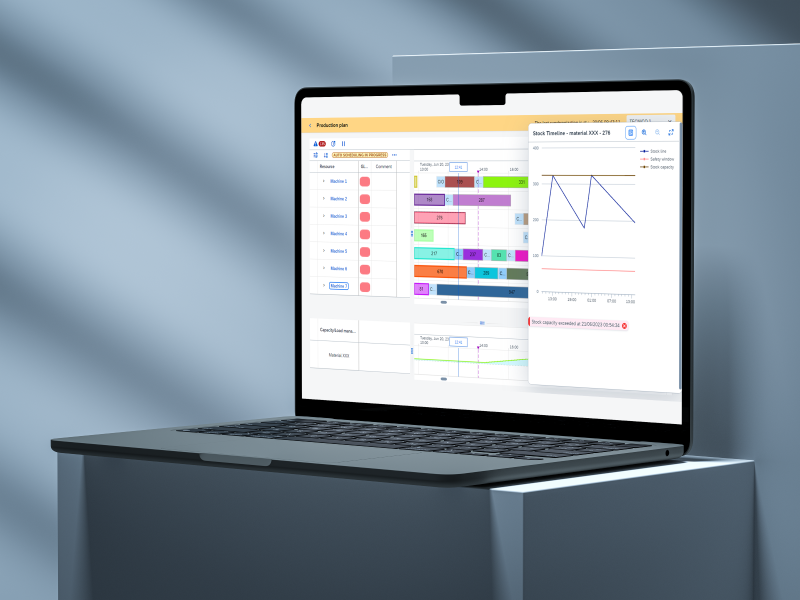

PlaniSense offers a complete solution to meet the challenge of responsiveness in a constantly changing industrial environment.

PlaniSense facilitates collaborative working and offers advanced simulation and scenario management features for fast, fluid and informed decision-making.

How we work

PlaniSense solution implementation times vary according to the functional scope to be deployed, but remain relatively short (around 3 to 9 months). This guarantees our customers control over integration costs and the risks inherent in deployment projects. We adopt an agile approach to stay as close as possible to user needs and prepare the ground for effective change management.

Framing

- Define project scope and objectives

- Define project success criteria

- Understand and master workflow and processes

- Define target solution

- Draw up a detailed project schedule

Incremental delivery

- Determine the content of each iteration based on the functionalities described in the backlog

- Progressively customize and integrate PlaniSense functionalities

- Deliver a functional version of PlaniSense after each iteration

- Collect and process user feedback after each iteration

Go-Live and Hypercare

- Validate User Acceptance Tests (UAT)

- Lead the transition to using the solution in a production environment

- Support users during the Hypercare support period

Three modules to suit your needs

The PlaniSense solution comprises three modules: Demand Planning, Supply Chain Planning and Scheduling. These modules can be used independently or complement each other, depending on the specific needs of each customer. Each module contributes, at its own level, to the overall improvement of the company's level of reactivity, thanks to advanced alert systems, simulation and collaborative work functionalities.

This module enables you to accurately forecast demand in order to maximize service level and anticipate capacity requirements.

In a context of finite capacity, this module enables mid and short-term management of distribution, production and supply to satisfy demand at the lowest possible cost.

This module enables you to sequence short-term operations and allocate resources to maximize efficiency and productivity.