Modern planning: the benefits of simulation and scheduling

Nov 26, 2024 3:41:44 PM - 5 min read

Zineb

A contradictory demand for production consistency and responsiveness to events seems to haunt the new trends in the Supply Chain. In a constantly evolving context, companies face a major challenge: how to reconcile consistency and responsiveness in their production?

This duality has become a central point in modern operations management. Historically, planning tools were designed with a focus on consistency, where planning is done hierarchically, starting from macro-level data (S&OP) to micro-level data (master production schedule, material requirements planning, sequencing, etc.). This logic, though seemingly flawless, was developed in a time when production complexity and uncertainty did not weigh as heavily on systems. This now highlights the limitations of these innovations and pushes us to look further.

The Traditional Model: Is Consistency Now Insufficient?

The traditional planning process relies on a hierarchical approach, where each planning level builds on the previous one. Sales and Operations Planning (S&OP) defines the strategic guidelines in terms of production and capacity, while subsequent steps, such as Master Production Scheduling (MPS) and Material Requirements Planning (MRP), translate these objectives into concrete actions on the ground.

However, in a world where demand constantly evolves, product personalization becomes essential, and uncertainties persist (Supply Chain disruptions, etc.), this approach reaches its limits. It is now critical to react swiftly to unforeseen events while maintaining an optimal level of consistency.

The Central Role of Scheduling in Responsiveness

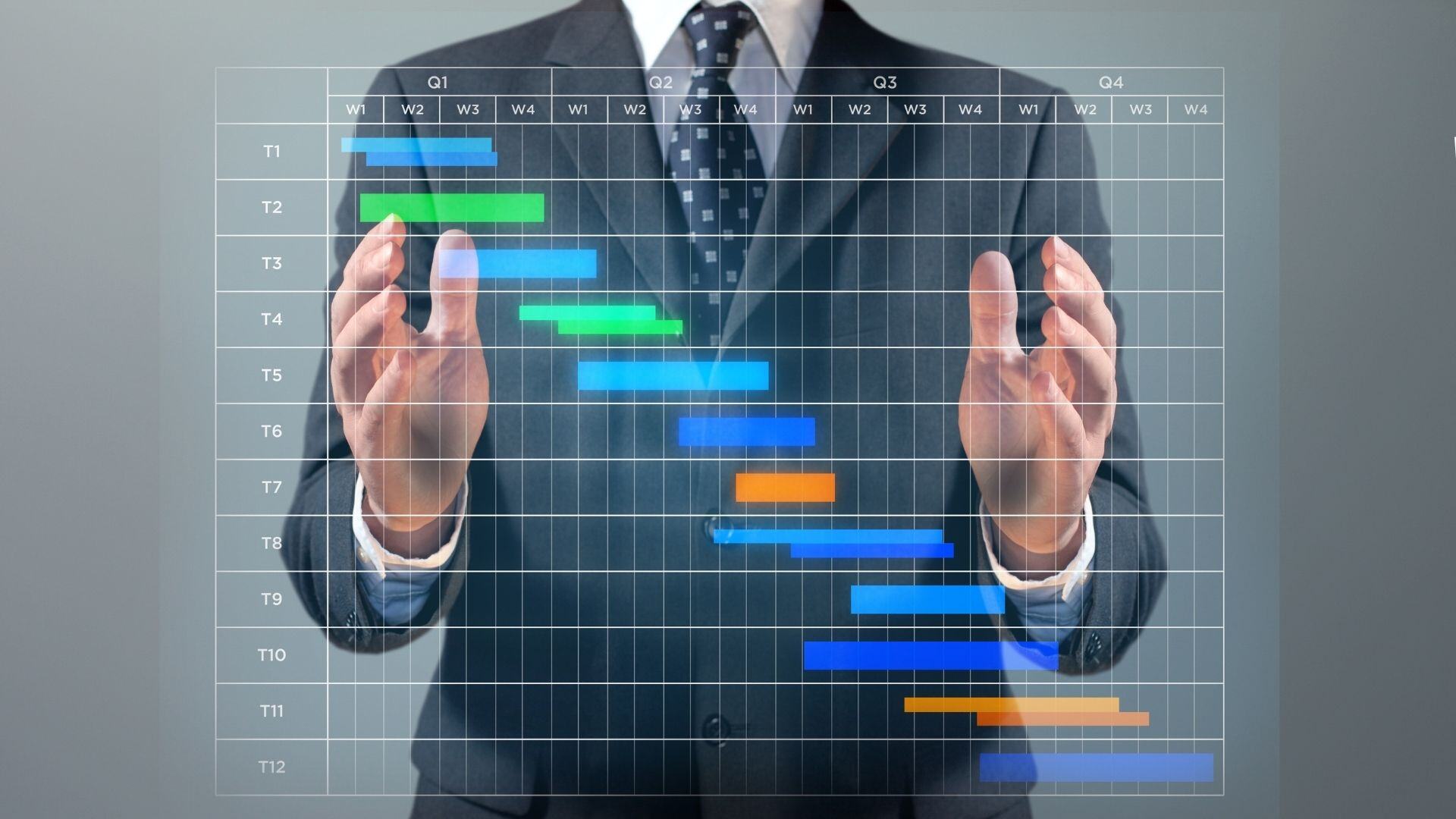

Scheduling, as the final step in the planning chain, plays a crucial role in reacting to unforeseen events. Unlike higher levels of planning, which are more strategic, scheduling works at the operational level, where decisions must be quick and precise. It is at this stage that alignment between production and actual constraints (machine capacity, material availability, setup times, etc.) is determined.

Advanced Planning and Scheduling (APS) systems are increasingly used to automate this critical step. They not only optimize resource use but also respond in real-time to production disruptions. A good scheduling system should be capable of recalculating the production schedule within minutes or almost immediately.

The Responsiveness Dilemma: A Contradictory Demand

The dilemma faced by companies can be summarized as follows: should they maintain strict vertical consistency in the planning process while attempting to respond to events in real-time? The pressure to maintain smooth operations, while managing disruptions such as sudden demand spikes or resource unavailability, creates a gap between the stability needed for production and the responsiveness demanded by the market.

This contradiction highlights a major challenge: without suitable tools, responding to real-time fluctuations while maintaining a coherent overview becomes a Herculean task. It is therefore essential to find a way to reconcile these two imperatives.

Simulation and Advanced Scheduling: A Joint Response to Complexity

This is where simulation, combined with advanced scheduling, comes into play as a key solution to resolve this dilemma. By offering the ability to model "What If" scenarios, simulation enables companies to reconcile consistency and responsiveness without sacrificing one for the other. It helps ask the right questions, assess the impacts of decisions before making them, and prepare for unforeseen events.

Advanced scheduling solutions, integrated into planning systems, can simulate various scenarios to respond quickly to unforeseen events while maintaining production chain stability. If a machine breaks down or a delivery is delayed, these tools allow recalculation of a new schedule that optimizes the use of remaining resources without affecting delivery timelines.

Benefits of a Combined Simulation-Scheduling Approach

Beyond their ability to reconcile stability and responsiveness, the combination of simulation and advanced scheduling offers several additional advantages:

- Resource Optimization: Advanced scheduling enables optimal use of machines and human resources based on actual field constraints.

- Reduction of Downtime: By simulating the impacts of breakdowns or material shortages, companies can adjust their production schedule in real-time to minimize idle time.

- Proactive Management of Disruptions: Modeling various scenarios of stock shortages, demand fluctuations, or maintenance helps anticipate and reduce negative effects on production.

- Accelerated Decision-Making: Thanks to simulation, alternatives are quickly evaluated, enabling informed decisions in very short timeframes.

- Improved Collaboration: Modern simulation and scheduling tools facilitate collaboration between different teams (planning, production, maintenance) to ensure that decisions benefit all stakeholders.

Dynamic Scheduling for a More Agile Supply Chain Planning

For companies, the dilemma between consistency and responsiveness is no longer inevitable. Thanks to simulation and advanced scheduling, they can manage disruptions while maintaining a coherent global view of their operations.

Advanced scheduling tools offer the ability to recalculate the production schedule in real-time, accounting for demand fluctuations or unforeseen constraints. Solutions such as APS, which integrate simulation and advanced scheduling functions, play a central role in this transition towards a more agile and intelligent supply chain.

In the near future, integrating simulation and scheduling will not just be an option but a necessity to navigate an increasingly uncertain and complex environment. Through these technologies, companies can optimize their planning and scheduling processes while remaining flexible and responsive to market changes.